Facts About Mhs - Material Handling Supply Inc. Revealed

Table of ContentsHow Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.Mhs - Material Handling Supply Inc. Can Be Fun For EveryoneMhs - Material Handling Supply Inc. Fundamentals Explained6 Simple Techniques For Mhs - Material Handling Supply Inc.See This Report about Mhs - Material Handling Supply Inc.10 Easy Facts About Mhs - Material Handling Supply Inc. Explained

This line is called the line of activity. forklift rental athens, ga. If all-time low of this line goes outside of the security triangle because a tons is also heavy or expensive, or since the forklift is not on a degree surface it will certainly tip over. An upright line extending from the facility of gravity of the vehicle-load combination should remain inside the stability triangular to stop the forklift from tippingThis stability triangle is made by attaching both front wheels and the pivot factor of the rear axle. The other principle to understand is the forklifts facility of gravity. Notice that the front and rear sides of the security triangle are high-lighted. When unloaded, the forklifts center of mass is right regarding below.

Heavier lots shift the facility of gravity forward also further. Raising the tons also shifts the center of mass ahead. In order to prevent the lift from tipping, the consolidated center of mass of the tons and the lift need to remain inside the stability triangular (at ground level) whatsoever times.

The Facts About Mhs - Material Handling Supply Inc. Uncovered

If you have a well balanced lots, the lots is not likely to influence the side-to-side center of mass. https://telegra.ph/Forklift-Dealer-Your-Trusted-Partner-in-Athens-and-Watkinsville-GA-04-30. However if you drive on a sloped surface, your facility of gravity can pass beyond the stability triangular and the lift might tip. Every forklift has an identification plate that provides important info concerning the vehicle

To be certain that the center of mass of your forklift stays inside the security triangular, do not try to lift anything larger than the recognition plate allows. Despite just how active you are, you must examine your forklift before using it. If you do locate something that can affect the safety of the lorry you must report it quickly.

Follow the operators manuals provided by the devices supplier. These manuals explain the risk-free operation and maintenance of forklifts. Keep in mind, the operator is in charge of the safe operation of the forklift. Do a pre-operation assessment prior to every change. If the forklift is utilized all the time, examine it either prior to each change or after each shift.

Mhs - Material Handling Supply Inc. Fundamentals Explained

It is completed in 2 components: the walk-around assessment, and, the seated inspection. OSHA does not call for documents of a day-to-day inspection. Yet it's a great idea to have a list to make sure you do not miss out on any actions. These checklists can also be saved as a part of the upkeep document.

Examine the condition of the tires. If the forklift is an outside forklift with pneumatic tires, inspect the atmospheric pressure and look for extreme wear on the tires. A tire with reduced air stress could trigger the lift to tip when a load is raised. So could a tire failing.

The Only Guide to Mhs - Material Handling Supply Inc.

Examine the engine for any type of signs of wear, loosened connections, or leaks. Look for cracks or defects in the forks, backrest, pole, and overhead guard. Inspect the recognition plate to make certain it is intact and legible.

Start the engine. Always begin the engine while seated in the driver's positionnever while standing together with the forklift. Check all assesses and alerting lights, and the battery or fuel level. Obtain accustomed to the controls. Lift and lower the forks, best site and turn the mast. Make certain that every little thing functions smoothly and is clearly classified.

5 Easy Facts About Mhs - Material Handling Supply Inc. Explained

You'll require to sound the horn at intersections, and wherever vision is blocked. Inspect the brakes by dispiriting the brake pedal. There must be some resistance. Set and evaluate the auto parking brake. Check the guiding. A great deal of play or tough guiding will minimize your control. Move the forklift forward a few feet.

Leaks could indicate a hydraulic issue, and liquids left on the flooring are a slipping danger. Likewise seek sparks or flames appearing of the exhaust system. Pay attention for any type of uncommon audios. If you discover anything incorrect with the forklift throughout the walk-around or seated examination, do not operate it until it has been fixed.

Not known Details About Mhs - Material Handling Supply Inc.

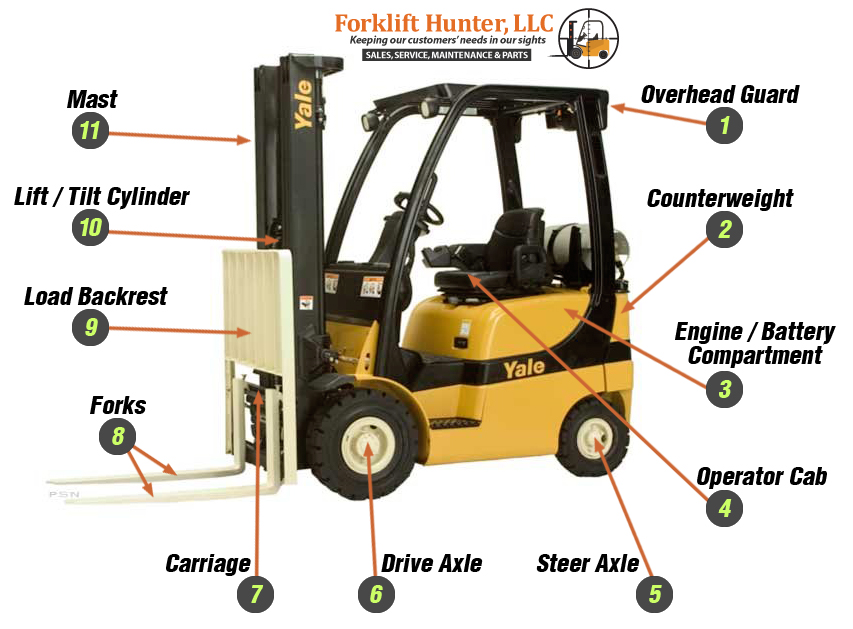

Forklifts have lots of moving components and items that enable the forklift to operate correctly. Recognizing the terms of the components and composition of a forklift is very important for efficient communication with others while on the work - https://www.cheaperseeker.com/u/mhsinc30677. Here are some of the essential features and components that comprise the composition of a forklift vehicle

For the majority of forklifts, the pole is designed toward the front of a forklift and directly in the forklift operator's field of vision. Forklift poles feature numerous areas that boost or lower the forklift carriage together with the forks. These include:: Two pole phases: 3 pole stages: Four pole areas When choosing a forklift, it is very important to acquaint yourself with the different attributes and terms of a forklift mast: the mast's lift height, the free lift elevation and the prolonged height and the reduced height.